详细介绍

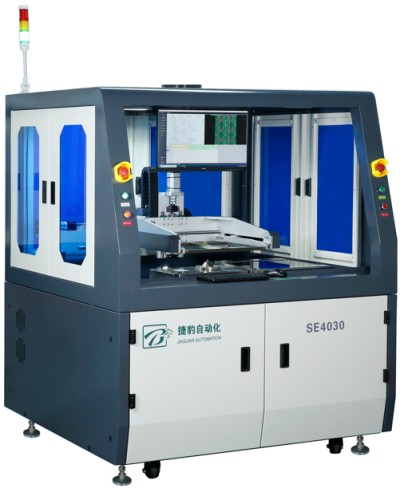

产品名称:选择性波峰焊 SE4030

产品名称:选择性波峰焊 SE4030

Product Name:Selective wave soldering SE4030

优势;节省能源, 节省助焊剂,无需工装夹具,焊接品质优越

Advantages; energy saving, flux saving, no jigs and fixtures required, superior soldering quality.

高度精准定位:采用先进视觉识别与运动控制技术,实现焊点精准定位,偏差控制在±0.15mm 以内,确 保微小、密集部件焊接位置精确无误。

Highly accurate positioning: Adopt advanced visual recognition and motion control technology to realize precise positioning of welding joints, with the deviation controlled within ±0.15mm, ensuring the precise welding position of tiny and dense parts.

出色灵活性:可根据不同产品需求,灵活调整焊接参数与路径。无论是简单几何形状还是复杂三维结构,都能轻松应对,满足多样化生产需求。

Outstanding flexibility: Welding parameters and paths can be flexibly adjusted according to different product requirements. Whether it is a simple geometric shape or a complex three-dimensional structure, it can be easily coped with to meet the diversified production needs.

优质焊接质量:严格控制焊接温度、时间与锡量,形成饱满、牢固焊点,有效降低虚焊、漏焊等缺陷,提 升产品电气性能与机械强度,提高成品率。

High-quality soldering: Strictly control the soldering temperature, time and amount of tin to form full, solid solder joints, effectively reduce defects such as false soldering and leakage soldering, improve the electrical performance and mechanical strength of the product, and increase the yield rate.

1.详细描述 Detailed description

·外型尺寸:1460*1320*1835mm

Outer size:1460*1320*1835mm

·主体颜色:主体灰色,门板白色

Main body color: main body gray, door panel white

·净重:350kgs

Net weight: 350kgs

·电源:单相; 220V 50/60HZ

Power supply: single phase; 220V 50/60HZ

·功率:启动功率 4KW 消耗功率 1.5kw

Power: Starting power 4KW, consumption power 1.5kw

·锡炉升温时间:约 30-40min

Solder pot heating time: about 30-40 min

·温度范围:270--320°C

Temperature range: 270--320°C

·PCB 最大宽度:300*400mm

Maximum width of PCB: 300*400mm

·操作平台高度:750±20 mm

Operating platform height: 750±20 mm

·参数存储:可存多种生产设置参数与状况

Parameter storage: can store a variety of production setup parameters and conditions

·异常报警:超高或超低温报警,声、光两种方式

Abnormal alarm: ultra-high or ultra-low temperature alarm, sound, light two ways

2.设备配置 Equipment Configuration

·加热;下红外线短波加热方式预热

Heating; lower infrared short-wave heating method preheating

·控制系统:WIN 10+PC 工控+新浩控制器

Control system: WIN 10 + PC industrial control + Xinhao controller

·温控方式:东奇温度模块 PID 闭环控制+SSR 驱动

Temperature control mode: Dongqi temperature module PID closed-loop control + SSR drive

·X Y Z 轴控制方式:松下 A6 伺服驱动

X, Y, Z axis control: Panasonic A6 servo drive

·锡波驱动方式:采用雷赛步进驱动

Tin wave drive mode: using Leadshine stepper drive

·X Y Z 轴控制硬件:上银模组加滚珠丝杆组合

X Y Z axis control hardware: Upper silver module and ball screw combination

·锡波高度,自动波峰高度校准

Tin wave height, automatic wave height calibration

·锡波液位,锡波液位低报警提示功能

Tin wave liquid level, tin wave liquid level low alarm prompt function

3.氮气系统 Nitrogen system

·氮气流量计:标配氮气流量计和氮气加热功能

Nitrogen flowmeter: Nitrogen flowmeter and nitrogen heating function as standard

·氮气消耗量,每小时 2 立方氮气消耗 0.2 –0.8Mpar

Nitrogen consumption, 0.2 - 0.8 Mpar per hour for 2 cubic meters of nitrogen

4.元件配件清单 List of component parts

|

|

品牌 brand |

品牌属地 brand belong |

|

控制部份 Controlling |

||

|

工控机 Industrial PC |

新浩 Xinhao |

中国 China |

|

控制器 Controller |

新浩 Xinhao |

中国 China |

|

监控相机 position camera |

奥视 Osee |

中国 China |

|

固态继电器 SSR |

佳乐 Carlogavazzi |

瑞士 Switzerland |

|

中继 box relay |

和泉 Hequan |

日本 Japan |

|

开关电源 switch |

明纬 Meanwell |

中国台湾 China-Taiwan |

|

断路器 contactor |

正泰 Chnt |

中国 China |

|

交流接触器 AC contactor |

施耐德 Schneider |

法国 France |

|

限位光眼 sensor |

松下 Panasonic |

日本 Japan |

|

运动部份 Motion parts |

||

|

伺服电机 Servo motor |

松下 Panasonic |

日本 Japan |

|

伺服驱动 servo driver |

松下 Panasonic |

日本 Japan |

|

滚珠丝杆 ball screw |

上银 Hiwin |

中国台湾 China-Taiwan |

|

直线导轨 linear guild |

上银 Hiwin |

中国台湾 China-Taiwan |

|

气动部份 Pneumatic |

|

|

|

压力传感器 Pressure sensor |

SMC |

日本 Japan |

|

气缸 Air cylinder |

亚德克 AirTAC |

中国台湾 China-Taiwan |

|

电磁阀 Solenoids |

亚德克 AirTAC |

中国台湾 China-Taiwan |

微信平台

微信平台